|

As a professional paving company in North Texas, we run across folks who are unhappy with the quality they've received on their driveways. Some think they've been scammed. Sometimes they have and sometimes not so much. Either way, the threat of being scammed these days doesn't feel good at all so here's a post that discusses it in more detail.

Being scammed is something we all live with the possibility of today. We know it can happen in pretty much any endeavor we take on in our daily lives. Still, we've all become accustomed to taking calculated risks with our online shopping, the payments we make, the contracts we sign, and the passwords we put on our computers just to name a few. Today, everyone does some due diligence, but eventually we have to make a decision to move forward. You don't want deferred maintenance... When it comes to driveway paving, putting it off because of fear is actually costing you far more than you think. The small puddle turns into alligator cracks and before you know it, expensive repairs are necessary to remove and replace damaged asphalt. The point is, it's not good to wait as deferred maintenance costs many times more than regular maintenance. Still, the buying process can be a challenge. How do you know you're getting a fair price? How do you know the work will be completed on time, and on budget? Honestly, it can be hard to know, unless you have some honest discussions with the companies your getting bids from, references, or other experts that you can rely on. You should still be getting multiple bids on any home improvement project as experts recommend. The trick is to avoid being scammed or getting shoddy work that you've paid full price for. What does not constitute a scam? It seems that most of the time, when we talk to disappointed homeowners in Texas, they haven't been scammed at all. There are usually underlying issues involved. Here are a few to consider... Underlying Water issues: An example would be a paving company that points out that a homeowner needs a culvert and the homeowner doesn't want to pay for one. They pave without it and as a result water rushes over and under the driveway eroding it prematurely. This is not a scam because the paving company did what they were contracted to do, despite telling the homeowner what they did actually need. Underlying base issues: Another example would be an asphalt overlay that cracks. Here in Texas we have very bad soil conditions and the weather takes a mighty toll on paving of all types here. When a newer asphalt overlay cracks, the cause is most likely due to the underlying base or dirt. This would not constitute a scam because to remove the existing asphalt can be very costly for homeowners and few are willing to take on the financial burden of removing an entire driveway to start from scratch. This isn't a scam unless the overlay was wafer thin throughout. A good company would come see what happened, but in the case of a paving scam they very likely wouldn't. Heavy Vehicle Traffic: When a dump truck, trash truck (especially one with one rear axle), or other heavy trucks and trailers drive on a driveway, the weight can damage the asphalt. This is especially true in the period of time before the asphalt is cured. Asphalt companies will ask you not to drive on a new driveway right away, and no heavy traffic should be allowed on it before it has time to cure. If asphalt is bending and breaking, it may not be the overlay or driveway, but rather the commercial traffic driving on it. This would not be a scam, but a good company could help you out and look at the damage and potentially fix it for you. A scammer wouldn't be reached for comment. "Weeds and water go where they want." If a company puts in asphalt and some grass or weeds make it through it's not necessarily a scam, but it can also be a tell-tale sign. Here in Texas, grass and weeds are pretty veracious, and they can make some asphalt seem like it was put on thin even when it wasn't. Additionally, a paving company with a good reputation could put in a driveway that inadvertently has a small area with thinner asphalt than it should, but a paving scam would involve a very thin layer throughout. If a paving company falls short in a small area and a few weeds poke through it would be more appropriate to categorize it as an isolated defect of workmanship and the company should be willing to remedy it. On the other hand, if numerous patches of thick grass and weeds grow though more consistently across the driveway, it is likely a scam, especially if the company will not be willing to make good on it. Remember... A quality paving company should be putting at least 2-3 inches of asphalt on top of a firm base and any weeds or grass that eventually make it through would be more sparse. A scam would involve very thin pavement throughout. A good company will address issues, a scammer wouldn't. What may be a paving scam? The best way to explain a paving scam is that it would be a combination of factors including a high-pressure sale where the company may say they have extra asphalt from another job or something and have to do the work immediately. This alone could be fine, but the scam part is that the price is high, and the quality of work low. In our book, that would constitute a scam - shoddy work for high dollars. Here are signs to look for that may lead to a driveway you're not proud of: • High-pressure sales • Unmarked trucks • Something is too-good-to-be-true • No written estimates • Door-to-door sales • Leftover product • Out-of-state plates or phone • Company doesn't pull up in Google • Company has high percentage of bad reviews • Not a company in good standing with the state Here are a few things you can do to get a quality paving contractor: • Check references or past work examples • Get multiple bids • Use a site such as HomeAdvisor to ensure contractors have passed a background check • Get a clear explanation of the work being bid • Let contractor know exactly what you're expecting • Get recommendations from the neighborhood sites you are a member of and check out their driveways. Hope that helps! Keep in mind, the vast majority of problems with paving and driveways in Texas isn't the result of a scammer, but is more often attributable to the existing driveway, the underlying road base, water issues or other factors that Texas has its fair share of that are cost prohibitive or not approved by the homeowner. Although there is no real way to officially warranty paving due to the water and soil issues here, a good company will stand behind their work and value their reputation. When they won't stand behind their work, don't have or don't care about their reputation, and also do work that is suspect, that's when things get scammy. Comments are open so you can leave your thoughts, too. When installing a pipe culvert for your driveway, private road, or other drainage needs, there are many materials available. Which material you choose can have a big impact on the culvert's longevity, so it helps to familiarize yourself with the main causes of pipe deterioration as well as the culvert materials most commonly used to combat them. Common causes of pipe culvert deterioration are corrosion, abrasion, and physical wear. Corrosion occurs when substances with non-neutral pH balances come into contact with metals, usually through soil or water contamination. When this happens, a chemical reaction causes metal pipes to rust, weakening the culvert. Metal culverts, in particular, are vulnerable to corrosion. Abrasion occurs when materials brought into the culvert by water, such as sand and small rocks, scrape against the pipe wall and damage it over time. The recurring bearing of heavy loads and other physical wear and tear can also damage pipes. If the material used to build the culvert has not been correctly installed or is not strong enough to withstand heavy loads driving over it, it may buckle or crack. Recurring temperature fluctuations (freezing and thawing) can also lead to structural damage. Certain materials will hold up to different forms of deterioration better than others. This article explains the three main materials used to build culverts—plastic, metal, and concrete—and their pros and cons in culvert construction. Aluminum and galvanized steel are popular culvert building materials. Corrugated metal is strong, reasonably affordable, and can be adapted to resist corrosion through galvanization. Still, there are some downsides to metal culverts. First of all, even when galvanized, metal corrodes and rusts over time, especially when the water or surrounding soil has a high or low pH balance. Additionally, metal pipes can be heavy, inflexible, and difficult to cut if they need to be trimmed to fit the culvert trench. Weaker metals will also buckle or warp over time, especially when the road in question supports heavy traffic. Plastic pipes are a cheaper, easier to install alternative to metal pipes. They are lightweight and flexible, allowing for easy transportation and installation. Additionally, plastic can be cut easily to fit any size of culvert trench. One downside to plastic’s lightweight nature is that erosion and the material’s natural buoyancy can cause it to become displaced over time. However, this displacement is easily avoided if the pipe is correctly bedded and the surrounding soil properly compacted during installation. Another benefit of plastic is that it does not corrode or rust like metal does and, so, can resist high and low pH balances. Whether you decide on metal or plastic, consider buying corrugated pipes. These pipes’ wavy pattern increases both materials’ flexibility and resistance to warping or buckling under weight. In most cases, corrugated plastic pipes will be a good fit for the job. Another type of plastic pipe, PVC, also has its uses. PVC is smaller and less flexible than corrugated plastic pipes. It is ideal for low water flow or when the water needs to be carried over great distances, as is the case in irrigation. Since clogs in long drainage pipes are more difficult to clear than short ones, PVC is also ideal when long pipes are needed because its smooth walls make it easier to clean than corrugated pipes. Concrete is far more expensive and difficult to transport, pour, and install (due to its weight) than either metal or plastic. However, it has its uses. Of the three materials, concrete is the most durable. Like plastic, it does not corrode. Additionally, concrete is resistant to warping and is able to bear heavier loads than the other two materials. Because of its durability and longevity, concrete pipe culverts are a good idea for those planning to install a concrete driveway or expect heavy traffic over the culvert. We don't see a lot of affordable full cement culverts here in Texas due primarily to the cost associated with them. Whatever material you decide to use when building your pipe culvert, proper research is key. Whether you choose metal, plastic, or concrete, make sure that the material fits your needs by consulting a trained professional. Additionally, hire a quality team to make sure the culvert is properly installed. A well-built culvert will be more effective in managing water flow and save you money in the long run by reducing maintenance costs.

If you live in a silt-heavy area prone to flooding, you may have experienced a clogged culvert on your property. Culverts become clogged when slow-moving or stagnant water deposits a large amount of sediment in the culvert pipe. If this sediment build-up goes unchecked, drainage can slow or stop entirely, leading to flooding and erosion in your yard and driveway or even on your neighbors' or public property. Here are a few strategies for dealing with a clogged culvert. First, check with your municipality (township, county, subdivision developer, etc.) to see if the culvert in question falls under their jurisdiction. If so, they are probably responsible for maintaining the culvert and will be able to clear it out or replace it for you. However, if municipal codes show that the culvert is your responsibility, you will have to hire a professional to clear the culvert, or do it yourself. If you do decide to try clearing the culvert on your own, there are a couple of available methods. First, if the sediment build-up is near the pipe’s exit points, you can usually use a shovel to clear it away, provided too much debris has not built up. Just make sure not to damage the culvert’s slope (culverts are higher at one end and slope down slightly at the other to allow for proper flow) in the process. When the clog is located deeper inside the pipe, solutions are less straightforward. One option is to make an extended shovel by welding pipe to the head of a shovel and inserting it in the culvert to clear away the debris. You can do the welding yourself or have it done in a local shop. There are also tools available online made specifically for cleaning culverts. This tool http://amzn.to/2xzqFvB has a hoe-type head that pivots at the joint. After being pushed into the culvert, the pivoting joint will cause the tool’s head to sink into the debris, extracting material from the blockage when you pull it out. Both the extended shovel and culvert cleaner options have been known to work. However, they are labor-intensive, often requiring extensive effort and help to finish the job. Check the reviews to make sure it's what you're after before purchasing. Another method for unclogging your culvert is to use a pressure washer or sewage jetter to blast the flow-disrupting materials out with water. Equipment like this is pricy, but you may be able to borrow something from the local volunteer fire department or other municipal department such as sewage or road maintenance. The downside to this method is that you may also need to secure a vacuum truck to remove the water and dislodged debris after unclogging so that it does not erode or otherwise damage the drainage area downstream of the culvert. A third common solution for a clogged culvert is to pull the blockage out using a chain and piece of piping. First, feed a strong chain through the culvert. This can be accomplished by punching a small hole through the blockage with a long pole that is attached to the chain. This allows you to pull the chain through the other side. Attach the end of the chain sticking out of the upstream culvert exit to a section of steel pipe with a diameter similar to but slightly smaller than the culvert pipe. Then, pull it through the pipe from the downstream end. The steel pipe will push against the blockage, forcing it out of the culvert as it is dragged through. Some debris may be wedged in pretty tight, often requiring a truck or other powerful vehicle to pull the pipe and blockage through. As with the other methods, the removed debris should be cleared from the drainage area to prevent future clogging in your or your downstream neighbors’ culverts. These are the three most popular do-it-yourself methods for cleaning out a clogged culvert. While removing a clog from either end of a culvert is simple enough, attempting to remove debris lodged deeper in the culvert is labor-intensive and requires expensive equipment. There is also a risk that these methods could do more harm than good by damaging the culvert pipe or the drainage area. For this reason, the safest option is to contact a professional to unclog or replace the culvert. Doing so will save you time and energy while also keeping you on the right side of municipal codes involving roads and drainage. Country Roads Paving is replacing damaged culverts and will install a new culvert in our work area in North Texas - Celina, Pottsboro, Pilot Point, Allen, Fairview, Prosper, McKinney, Anna, Melissa, Sherman, etc. Just request a free estimate if you're interested.

County websites in our area: Collin County Culvert Forms & Permits http://www.collincountytx.gov/development_services/Pages/culvert_forms.aspx Denton County Culvert Noms & Permits https://dentoncounty.com/Departments/Public-Works-Planning/Applications-and-Permits.aspx Grayson County Culvert Forms & Permits http://www.co.grayson.tx.us/default.aspx?name=tre.payment_culverts When determining who should handle your driveway culvert maintenance, the key is knowing who owns and is responsible for the land on which the culvert is located as is laid out in the town or county’s government policies. Many people avoid researching such policies because they don’t want to deal with all that legal jargon. However, this article equips you with the information you need to navigate government resources concerning culverts. First of all, it will be helpful to familiarize yourself with some key terms concerning culverts and drainage policy:

Now that you are familiar with the key terminology surrounding culvert maintenance policies, it’s time to find the correct city or county department to contact. Usually, the information you’re looking for can be found by contacting the government department in charge of road regulations. A good place to start is your county’s government website. This can usually be found by using an online search engine to search the name of your county followed by 'official website'. In the search results, the website you’re looking for will usually be one of the top results. It should also plainly state the county’s name. For example, when I searched 'Randall County, TX official website' the county’s government website, www.randallcounty.com, was the first to pop up. Once you’re on your county website’s main page, you will usually see a 'Departments' tab or something similar. Click this tab and scroll down until you find the department title related to roads, streets, or drainage governance. The exact name of this department will vary county to county, but it should be pretty easy to spot. On Randall County’s website, the proper department can be found under 'Road & Bridge'. Once you’re on the correct department page, you’ll usually see the names of government officials as well as their contact information. The fastest way to get your questions answered is to call them directly (it’s up to you whether you want to call the head of the department or other available contacts on the list). However, you may also send an email if you prefer. When speaking with (or emailing) a representative from the department, there are a couple of questions you should ask right away. First of all, confirm that you’ve found the correct department by asking them if they are responsible for upholding regulations surrounding culverts. If they are not, ask them to transfer you to the correct department or, at the very least, get the name and contact information for the department you need to call. Once you have confirmed that you are talking to someone who can help you, tell them about your situation and why you want to know who is responsible for culverts in your area. Whomever you talk to will probably want to know your address as well as if you own the property in question, as regulations usually vary depending on who owns the property as well as the property’s location (township, county, subdivision, etc.). They may also ask if you know of any drainage easements on or near your property. Additionally, you should let them know if your culvert’s malfunction has damaged anything on your, your neighbors’, or government property. With this information, the government representative should be able to answer your questions or direct you to someone who can. Even when you have your answer, it doesn’t hurt to do some independent research to confirm what you’ve been told. This involves using a search engine or public files (usually obtainable at a courthouse or other location of public records) involving land development/drainage codes, policies, and regulations. On the Randall County Road & Bridge Department webpage, this information is readily available. It can be downloaded as a PDF via the Road & Subdivision Policy link, found under 'Information' in the page’s left column. If your county’s website isn’t as straightforward, you can politely ask the department representative with whom you speak to direct you to where the policy can be found. There should be no reason they cannot do this. However, if for some reason they can’t help you, you should be able to find the information online by searching the name of your county, plus “culvert policy” or something similar. If possible, find the original policy scanned online as a PDF. Use the Table of Contents to find the section related to culverts and drainage, and read through it. This will help you feel more informed as you move forward in repairing or replacing your faulty culvert. Sometimes, the terminology used in the policy can be pretty convoluted or dull. However, stick with it, and use the key terms from this article to help you. The policy will usually describe who is responsible for different types of properties and culverts, as well as the permits and other steps one should take in order to comply with regulations. In our Randall County example, if the culvert is located on private property, the owner of that property is responsible for the culvert’s upkeep. If a culvert is located in a subdivision, the subdivision developer is responsible for maintaining culverts and must do so in keeping with the city’s code. Meanwhile, culverts on public land are the responsibility of the government. According to Randall County Law and Ordinances, inspectors are required to check all culverts on public land once a year. Additionally, if someone notices a problem with culverts on public land, they should contact Law and Ordinances to resolve it. These are some fairly common regulations. However, every county’s laws are slightly different, and loopholes abound, so do your best to get the information specific to where you live. Best of luck!

Keep in mind, we're a paving company with good standing with the state of Texas and the local communities we serve so if you have more productive things to do with your time than mess with the driveway, have us come out and do a free estimate. Additionally, these fixes are on the 'temporary' side. More permanent fixes are available with hot mix asphalt if preferred. Also... know the risks: There may be safety concerns for homeowners who choose to do their own driveway repair such as exposure to chemicals and irritants, damage to people, wires or pipes, or real estate due to heavy equipment, or incorrectly diagnosed or completed repairs. Have you asked yourself any of the following questions? • How do I fix alligator cracks in my asphalt driveway? • How do I repair a pothole in my asphalt driveway myself? • How can I seal coat my own asphalt driveway? How to fix my own driveway - The following offers a step by step overview of how to approach repairing your own damaged driveway: When it comes to asphalt driveway repair and maintenance, there are three main types of damage to look out for—alligator cracks, potholes, and sinkholes/birdbaths. Alligator cracks (sometimes called spider web cracks) are fine fractures that appear in the asphalt’s surface. They can result from wear due to fluctuations in temperature, heavy traffic, or even faulty construction. Alligator cracks may not be noticeable when you’re driving over them. However, they don’t look nice and, if left unchecked, can turn into potholes over time. Potholes result from untended alligator cracks. Potholes are simply holes where the asphalt has been broken and worn away. They can make for bumpy driving and sprained ankles if you trip on them. Potholes are disruptive, and usually grow larger if left unchecked. Sinkholes are similar to potholes in that they ruin the flatness of a driveway's surface. However, they are caused by different factors. A sinkhole forms when the base foundation beneath the asphalt has worn away due to erosion, poor construction, or other variables. The depression left behind still contains the material of the road surface. However, due to the unstable base, the affected section of driveway sinks. Small, less serious sinkholes are sometimes called birdbaths (usually 1” to 2” deep). Alligator cracks, potholes, and sinkholes all require unique methods of repair. Fixing alligator cracks To fix pesky alligator cracks, you’ll need the correct materials—alligator patch, sealcoat, and a squeegee. In general, one gallon of alligator patch material can cover 20 square feet. Make sure you consult with a professional to learn what type of and how much patch you’ll need before making your purchase. As for asphalt squeegees, they are pretty affordable. The standard sizes used are 24” and 36”. You may also want to grab an old paintbrush for places the squeegee can’t reach. For alligator cracks and all other types of driveway damage, you'll want a quality sealcoat to strengthen more repair. More on sealcoat in Step 3 of the alligator crack repair instructions! Have you gathered your materials? Let’s get started! Step 1: Clean your driveway! Make sure the area is free of dirt and debris such as weeds, as these materials will prevent the material used to repair the driveway from adhering properly. This can be accomplished with a broom or leaf blower. It may be tempting to use a hose or pressure washer to clean, but keep in mind that getting water in the cracks in your driveway can do more harm than good, particularly in areas where rapid changes in temperatures cause water to expand and contract. If you do choose to use water to clean the driveway, ensure that the area is completely dry before sealing any cracks, as moisture will cause additional damage. Step 2: Lay your patch Pour the alligator patch you have purchased to fill the cracks in areas needing repair, and use your asphalt squeegee to spread it evenly until the layer is 1/8 to 1/4“ thick. Use the squeegee to blend the new material into the existing, undamaged driveway surrounding the trouble spot. You can also use bottled crack filler to fix small cracks. Use a scraper to level off and spread this product. No matter which method you choose, allow several hours for the material to dry. Step 3: Sealcoat Using a sealcoat (also called sealant or sealcoating) is technically optional, but most experts agree that it contributes greatly to the longevity of your asphalt driveway. Sealcoat is made of coal tar pitch or asphalt cement mixed with fillers. The sealcoat protects the driveway surface and also makes it look nicer by giving a finished appearance to the entire surface. If you do choose to use a sealcoat, here’s what to do: First of all, you must wait until the repair material has had time to harden and fuse with the surrounding driveway. Depending on the patch you use and professional recommendations, waiting for the proper time to apply sealcoat after a repair varies from 4 to 8 weeks or even up to 2 years. Remember, asphalt maintenance is a journey, not a one time event! Once the product you use to fill in the alligator cracks is dry, you’re ready to lay the sealcoat. Working from the top of your driveway, pour the sealcoat in a line parallel to the garage door and use your squeegee to spread it evenly over the driveway working towards the road. For edges and hard to reach corners, use an old paintbrush. Make sure you exert enough pressure on the squeegee to spread the sealcoat thinly, but not so much that it oozes over the squeegee’s edge. When finished, allow at least 48 hours for the sealcoat to dry. Going along with that, make sure you choose a period of time in which no rain is expected, as precipitation will throw a wrench in your driveway maintenance plans. Check out our article about DIY seal coating for more detailed information! Fixing Potholes For potholes, you will want to purchase some cold asphalt patch. This usually comes in 50-lb bags and can be picked up at hardware or home goods stores such as Lowe’s. You will also need an asphalt tamper and sealcoat, if you wish. Step 1: Clean, clean, clean! As with alligator cracks, make sure your driveway is free of dirt and debris before beginning the repair. Step 2: How big is your pothole? Ten pounds of patch usually covers a square foot of pothole at a depth of 1". If the pothole is deep enough to reach the driveway’s base layer (usually made of gravel, dirt, or concrete), use sand or gravel to fill it in until it's level with where the asphalt layer begins. This will save you costly pothole filling material! Step 3: Pour your pothole patch. Pour your pothole patch into the hole, making sure to overfill by 1 to 2”. You can use a rake or other flat-headed tool to spread the patch material if necessary. Step 4: Compound your patch. Using your pothole tamper, compact the patch material so that it won’t crumble later on. Feel free to top off the hole as you compact the patch until the compacted patch is level with the rest of the driveway. Be thorough when compacting your patch, as doing so will increase the longevity of your repair. Step 5: Follow up with Sealcoat. Check out our article about DIY seal coating for more detailed information! As you did with repaired alligator cracks, use a good sealcoat post-pothole repair to protect your driveway! Fixing Birdbaths The term ‘birdbath’ is used to describe small sinkholes (usually less than 2” deep). Birdbaths can usually be repaired with the same material that is used to fix alligator cracks. Here’s how to do it: After cleaning out the birdbath depression, apply a layer of patch about 1/4” thick. Let it dry completely, which can take up to eight hours but depends on temperature and humidity, before applying another layer at the same thickness. Repeat the procedure until the patched area is level with the surrounding driveway. Then, apply a sealcoat. Fixing Sinkholes Sinkholes are depressions deeper than 2” and require pothole patch to repair correctly. Step 1: Know your sinkhole! Take a look at the sinkhole cracks. If the depression has cracks only around the perimeter where the material broke away from the surrounding asphalt, you can proceed with the following instructions to fix sinkholes. However, if the material in the sinkhole has fractured, you will have to use a pry bar or other tool to remove the chunks before moving forward with your repair. After removing these pieces, you can repair the sinkhole as you would a pothole. Step 2: Have the right tools for the job. Because sinkholes are less stable than potholes, repairing them can be tricky. Instead of a pothole tamper, consider renting a plate compactor or roller to compact the patch, especially if you’re dealing with a shallow sinkhole where the patch might not have as much sticking power. This will increase the longevity of your repair. Additionally, if the sinkhole goes past the layer of asphalt into the driveway’s base layer, don’t use sand or gravel at the bottom of your repair as you might when repairing a normal pothole. Instead, use patch material all the way through to increase stability. We generally caution homeowners from fixing serious items like this on their own. It's a safety thing and there may be unforeseen consequences from not hiring a professional. Step 3: Sealcoat As with repairs made to alligator cracks, potholes, and birdbaths, use sealcoat to seal up your repair and protect your driveway. Check out our article about DIY seal coating for more detailed information! A final not about sinkholes: Sinkholes can seriously undermine the integrity of an asphalt surface. If the sinkholes in your driveway are too extensive, it is probably best to tear up the bad asphalt and rebuild the foundation to the level of the surrounding base before filling with patch. Keep in mind that this method is time and energy intensive and usually requires equipment rental, so it may be better to hire a professional if you want those big sinkholes filled in properly. There you have it! An overview of what you need to repair your driveway, and how to do it!

Driveway Seal Coat Information, How to, and Pro's and Con's. Many homeowners wonder whether or not it’s worth it to get a seal coat (also called sealcoating, sealcoat or sealant) for their asphalt and concrete driveways. Sealcoat may seem like an extra expense. However, experts agree that proper application of seal coat is a fundamental component of driveway surface protection. The average life expectancy of a paved driveway is about 15 years. However, high quality and timely sealcoating and crack repair may as much as double the lifespan of a driveway! What is sealcoat? Sealcoat is a thin layer of material applied to finished asphalt or cement surfaces. It is made of either coal tar pitch or asphalt cement combined with fillers, water, emulsifiers, and other additives. Seal coats can be purchased at most hardware stores or from driveway servicing providers, who usually have their own custom formulas. Professionals use large tanks of premium tar instead of buckets sold in stores. Sealcoats are applied to protect driveways from damage caused by gasoline and oils, salt, water, and UV rays. Additionally, sealcoats improve the appearance of asphalt driveways, in particular, by hiding discoloration (usually caused by pavement oxidization over time) under a neat black finish. The most notable benefit is sealing small cracks and fissures so that water cannot easily penetrate through, which can cause more serious cracking and erosion of the top layer of driveway asphalt. Larger cracks can be filled with hot rubber which repairs deep cracks and prevents small cracks from growing into larger ones. What are the benefits of a sealcoat? In addition to improving a driveway’s appearance by giving it a uniform color and texture, good sealcoats slow oxidation by filling the small spaces between particles on the driveway’s surface. This keeps oxygen and the sun’s rays, as well as oil, gas, and other destructive elements, from sinking into the pavement’s surface. Similarly, sealcoat protects from water damage, in which water soaks into and enlarges existing cracks, particularly in areas where temperatures fluctuate between thaws and freezing. How often should I apply sealcoat? Most experts recommend applying new sealcoat every two to three years, depending on extreme weather and heavy traffic. When should I apply sealcoat? Before applying sealcoat to a paved surface, you may need to repair any damage, such as potholes or alligator cracks, existing in the driveway’s surface. This is particularly important if the cracks go through to previous asphalt layers or all the way to the dirt below. Remember, sealcoat is a protective layer. It is not meant to repair structural problems in your driveway. Experts differ in opinion on how long you should wait to seal your driveway after finishing repairs. Some claim you should wait six to twelve months, while others say you only have to wait four to eight weeks. Your best bet is to check the instructions on the sealcoat you purchased or ask the professional you bought it from for advice about that particular formula or ask your paving expert. Waiting the proper amount of time before applying sealcoat is necessary in order to let all areas repaired with hot mix to properly harden and fuse with the surrounding surface. How do I apply sealcoat? Because sealcoat is water-soluble, it should be applied at a time when there will be no rain for at least 48 hours. Beware of lawn sprinklers as well, as they can interfere with proper sealcoat application if used 48 hours before or after the sealcoat is applied. Additionally, choose a time of year where extreme temperatures will not affect the sealcoat’s ability to dry and cure properly. Good conditions are usually thought to be when the temperature is in the range of 60 degrees Fahrenheit. Sunny weather is ideal, as sunlight helps the sealcoat cure faster. When can I drive on it? Driving over a drying sealcoat should also be avoided when possible, but even thought the material would not be cured, in hot and dry weather, sealcoat may be dry enough to drive on in as little as 30 minutes after application. In most cases, it is recommended to stay off a recently seal coated driveway for a full day if possible. How can I apply sealcoat DIY style? To apply sealcoat, you will need mixed sealcoat (check the instructions for mixing on the sealcoat you buy, as how to prepare the material varies by product), as well as an asphalt squeegee, gloves, a face mask, and protective eyewear. You may want one of the white protective suits as well to avoid ruining clothes and to avoid the irritation that can occur with exposure to the product. You may also want to bring along an old paintbrush to get those tricky edges and corners. After ensuring that your driveway is clean (you can use a broom or leaf blower, but be cautious with pressure washers, as your driveway must be completely dry before you can apply sealcoat), retrieve your prepared sealcoat. Working from the top of your driveway, pour the sealcoat in a straight line in front of where you will be spreading it, and use your squeegee to smooth it evenly over the driveway. For edges and hard to reach corners, use the paintbrush. Make sure you exert enough pressure on the squeegee to spread the sealcoat thinly, but not so much that it oozes over the squeegee’s edge. When finished, allow 48 hours for the sealcoat to dry and cure. You can apply a second coat if desired (and if recommended in the instructions). A note about oversealing: If you use sealcoat too often, it can cause more harm than good. Oversealed driveways develop cracks in the layer of sealcoat (thought not in the asphalt beneath). These cracks look unsightly and can run pretty deep. Remember, your driveway doesn’t need new sealcoat more often than once every two years. Save yourself the time and money, and just wait until it’s necessary. How do the professionals do it? The biggest difference between DIY sealcoating and professional sealcoating is that professionals use spray tanks. Edges are still done the same way, but large areas are evenly coated with a large tank that feeds a high pressure spray wand. Professionals also generally fill deep cracks with hot rubber that is not commonly available to DIY'ers. Concrete Driveways The process of sealcoating a concrete driveway is a little different than that used on asphalt. First of all, concrete sealcoat lasts longer—about four to five years. As with sealcoating asphalt, you need to repair and clean your concrete driveway beforehand and wait until a period of dry, temperate weather to move forward with the sealcoat application. A note on selecting sealcoat for concrete: A penetrating concrete sealcoat is a good choice for older driveways. Over time, concrete becomes more absorbent, allowing penetrating sealcoat to soak in and prevent water, oil, gasoline, and other liquids from causing damage. Make sure you understand the instructions for preparation and application of your sealcoat. Concrete sealcoat is usually applied with a sprayer, so it’s important to wear protective gloves, a face mask, and eye protection as well. Move the sprayer in a back and forth sweeping motion to ensure that the product is applied in an even, thorough fashion. Pro's and Con's

A Final Word

There you have it! This article has given you the knowledge you need to make an informed decision about whether or not to sealcoat your driveway. Remember to defer to your specific product’s specifications to find out mixing instructions and the amount of product that will be needed for your paved space. Lastly, when it doubt, consult with your local driveway maintenance company. Recycled asphalt (sometimes referred to as 'crushed asphalt') is old roadway that has been removed and crushed at an asphalt plant. It goes from large compacted chunks to a granular product like you see here: An asphalt plant accepts deliveries of our old highways and they end up crushed into a big pile like this: The material retains the tar from the former road so it can be mixed with new asphalt, or used in new and different ways. Presently, driveways, walking paths, RV or boat pads, and rural parking lots are using recycled asphalt to create a dust-free semi-solid surface doesn't get muddy. When it first gets delivered it has a darker look to it but as time goes on it lightens up. This next photo shows a new pile being put on top of one that is a few months old: After a driveway, ranch road, or rural parking lot have been covered by recycled asphalt it begins to tighten up as heat, water, and humidity help filter the finer particles downward and harden them. Even though it begins to turn back into a road it will continue to have a thin layer of looser small rock at the top:

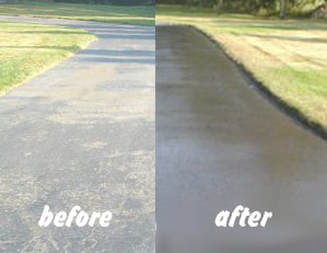

When a hot mix asphalt driveway starts showing signs of age, if the damage isn't too severe it can be paved over. We have to spend time preparing the driveway beforehand by addressing the most damaged spots so an even coat of asphalt can be applied. For this job, we had a mix of damaged surfaces, so lot of prep was needed. Hot mix asphalt is a bit of a challenge when it's over 100 degrees outside, but we think this one turned out amazing!

Congrats go out to this homeowner as they wrap up construction on their newly paved home. This involved grading out some material that was there, putting in a few drain pipes, and paving recycled asphalt through a paving machine and compacting. Low price compared to concrete or hot mix, but fits into the country surroundings perfectly. Looks amazing!

It's a good idea to fill any cracks in your cement driveway before they become bigger issues and now is a great time to do it. Winter can expand and contract cracks and make them worse so a few minutes outside could help out a lot. Believe it or not, just a few dollars in supplies and you could extend the life of your driveway not only a year or two, but the repairs although they may not hold forever, the lifespan could be extended by many, many years if you keep on top of it from time to time. Here's the most basic instructions you could ever find: • Clean the driveway - use a leaf blower, broom, and whatever you need to to clear grass and debris from cracks. • Use a wire brush or hard broom to remove pieces that are very loose. The idea is to have a clean, solid surface for filler to adhere to. • Fill small cracks with a textured caulk, a liquid concrete, or a concrete sealer. • With deep cracks you have a few options. The first of which is to decide if you could fill the crack with sand partially so that the crack has a solid base again instead of voids. Visit your home improvement store or look for the best products online. There are consumer product choices such as vinyl concrete patch, concrete grout, and driveway caulk to choose from. Follow the directions on the product and fill cracks as recommended. That's the quickest summary to get you started, but here's the key: The pressures OFF! That's because any repair you do to the cracks will be better than letting another year come and go without doing anything! P.S. If you need better instructions or a second opinion there are many articles online and you can always call a cement installation company for their opinion. |

Country RoadsRural drives and private roads are our passion. We post recent jobs, paving techniques, and tips and tricks here. Enjoy! Archives

January 2023

Categories

All

|

RSS Feed

RSS Feed